What is air lock and how to avoid it?

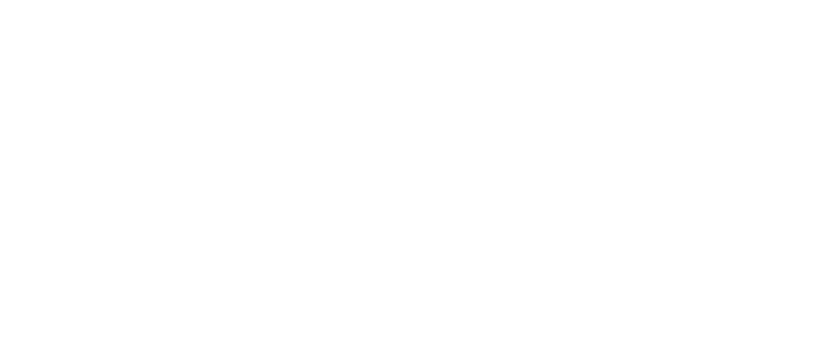

1. Under normal circumstances, the condensate water in the equipment flows into the cavity of the drainer along the lower edge of the drain pipe wall by gravity;

2. The compressed air in the cavity of the drainer returns to the equipment through the upper edge of the drain pipe.

3. Start draining when the liquid level reaches the high level of the drainer, and stop draining when the liquid level drops to the low level.

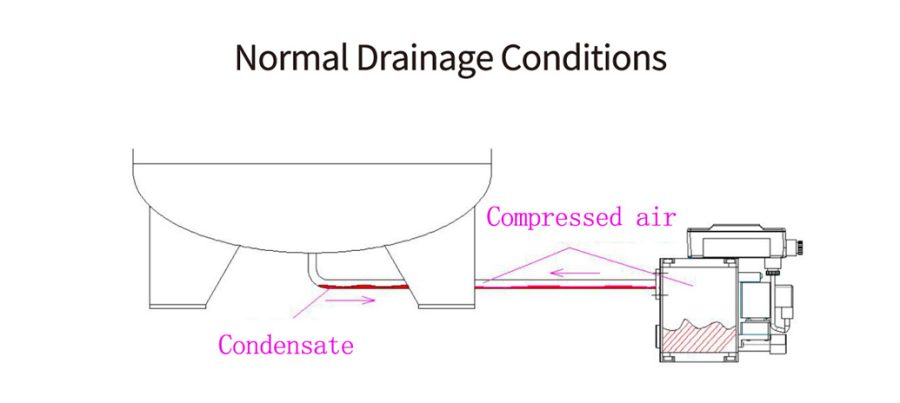

1. When there is too much condensate water in the system, or a stream of water enters the pipe due to installation problems, an air lock is formed.

2. The left and right sides of this water are compressed air with equal pressure. It is difficult to flow by gravity, which leads to a backlog of condensate water in the front-end equipment and affects the safe use of gas.

Ways to avoid air blockage

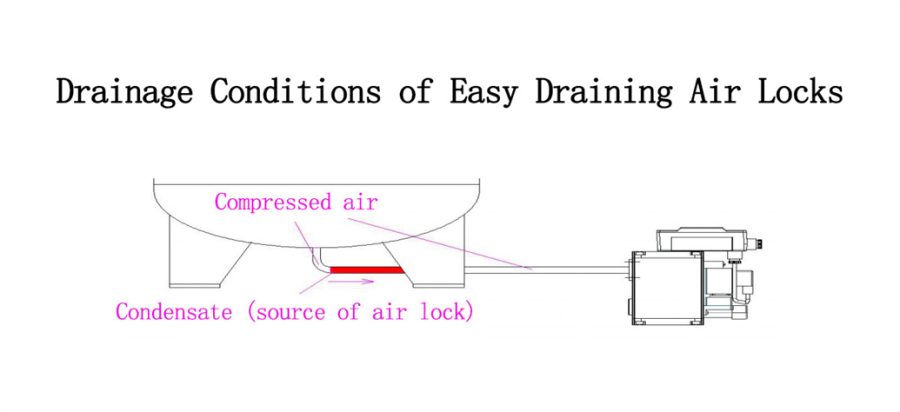

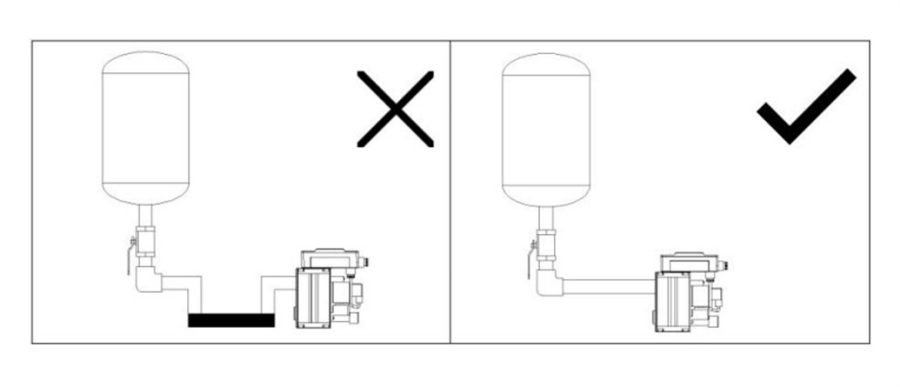

When connecting the water inlet pipe to the drain, be sure to avoid forming a water bay.

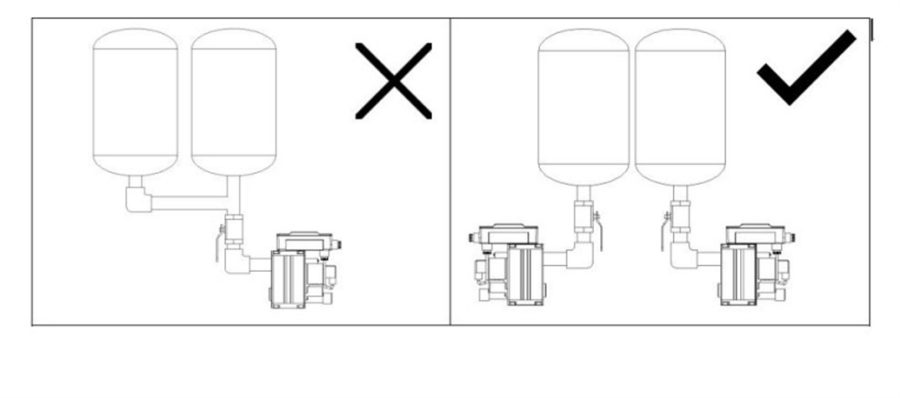

Different equipment cannot share the same drainer because there is a pressure difference, which may cause equipment with low pressure not to drain properly.

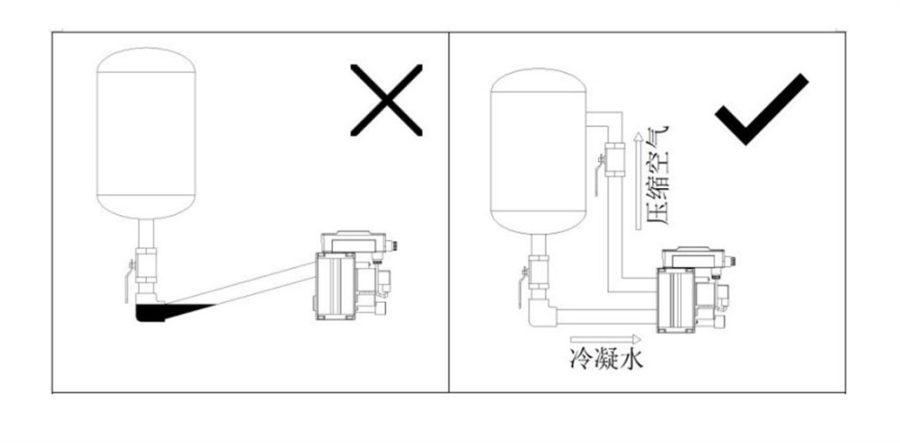

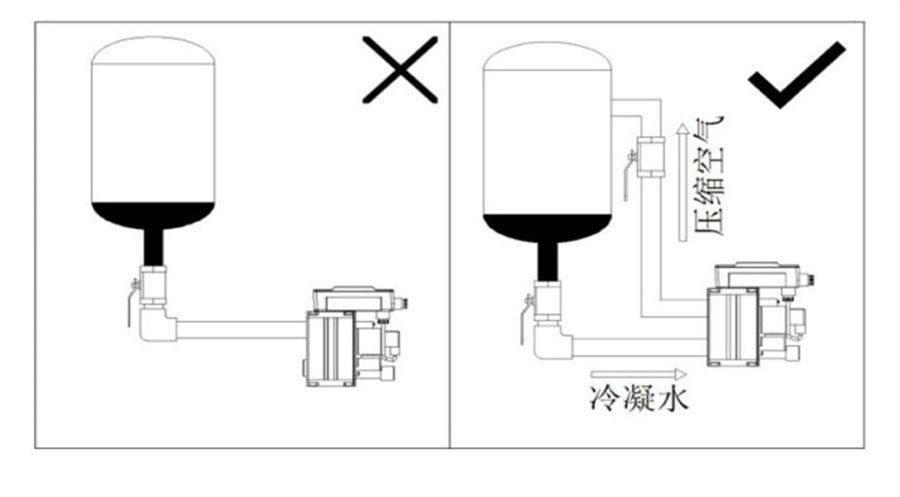

The water inlet pipe must avoid rising and forming an water bay; if the installation height is not high enough, please install a return air pipe.

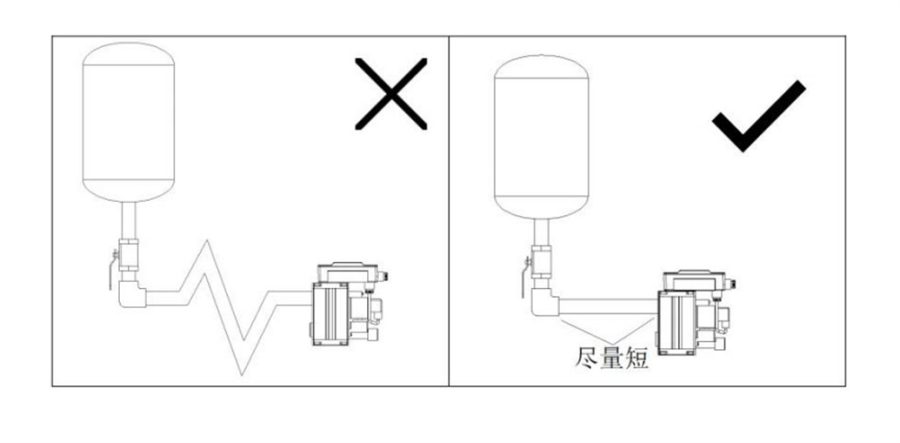

The inlet pipe should be short. If the water inlet pipe is too long, it will easily form an water bay and results in blocking water inflow.

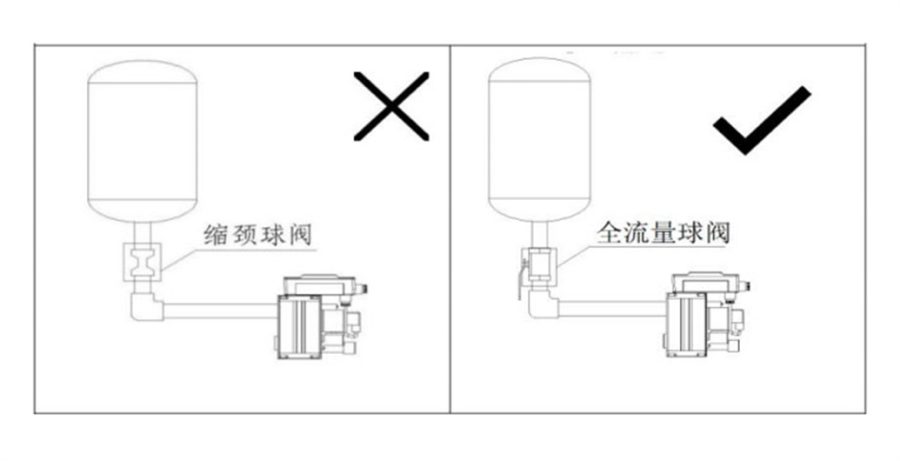

For the ball valve in front of the drain inlet, please choose a full-flow ball valve without neck reducer.

When draining large amounts of condensate, install a return pipe.