Why Choose Zero-gas Consumption Condensate Drain ?

The compressed air system will precipitate condensation water during the working process, and the condensation water contains oil and granular impurities. If the condensed water cannot be discharged in time, the quality of the gas will be seriously affected. There are many ways to discharge condensate, such as installing manual ball valves, electric ball valves, electronic drain valves, etc. However, the amount of condensate discharge is not static and fluctuates with various factors such as temperature, humidity, and compressor full load rate.

If you choose manual ball valves, electric ball valves and electronic drain valves, a certain degree of compressed air loss will occur, so we recommend that you choose the zero air consumption drainer produced by Dostar to avoid unnecessary compressed air loss.

How much cost can we save by using a zero-gas consumption condensate drain?

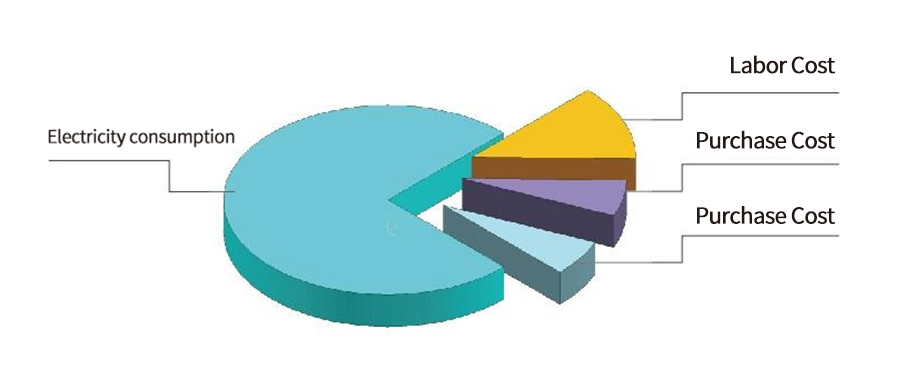

The following figure shows a ten-year cost structure of a compressed air system:

As a secondary energy source, compressed air is a fairly expensive power source. Taking a 75KW air compressor used for 300 days a year as an example, only the electricity cost can be as high as 75KW* 7200hr = 540000kw. In addition to other expenses such as purchase and maintenance, the unit cost of compressed air per cubic meter exceeds 0.12CNY/ m³.

Example 1: The current drainage status of the gas storage pipe: the 1/2” ball valve is drained in a slightly open state for a long time. Calculated based on the 3mm exhaust hole diameter, when the system pressure is 7 bar, the amount of air leaking from the manual drain valve is 0.64 m³/min , based on 300 days of using time per year, the total cost of compressed air lost each year is: 0.64 m³/min × 60min/hr × 7200hr × 0.12 CNY/ m³ = 33178 CNY/year

Example 2: The current refrigerated dryer is equipped with an electronic timed automatic drain. The drainage status is 5 seconds every 2 minutes, and the drainage hole diameter is 6mm. When the system pressure is 7bar, the leakage at the drain is 2.56 m³/min, then the annual air The leakage amount is: 2.56 m³/min x 2.5min/hr x 7200hr/year = 46080 m³/year. Estimated based on the average effective drainage rate of 40%, the annual drainage loss is: 46080 m³/year × (1-40%) × 0.12 Yuan/ m³=3318 CNY/year

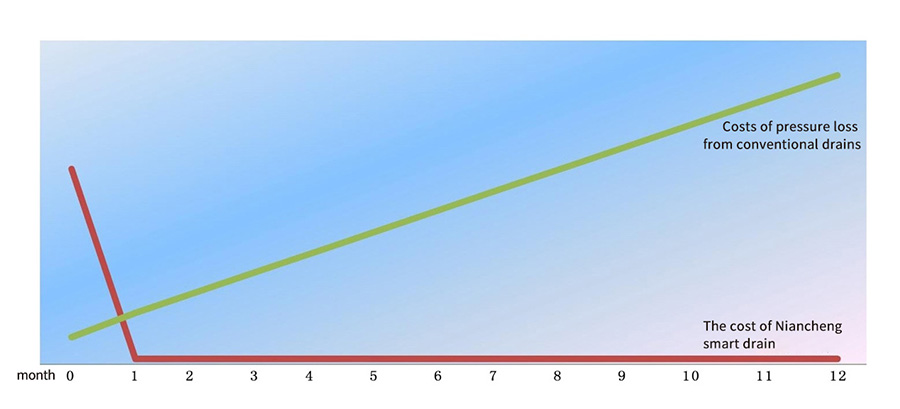

Long-term use of air-consuming drains not only causes a waste of energy, but also causes a series of problems such as increased energy costs, fluctuations in system pressure, reduced life of the air compressor, and increased maintenance costs. Choose Zero-air consumption drainers are completely necessary.

What are the advantages of the zero air consumption drain device produced by Dostar compared with other manufacturers?

Dostar Smart Drain adopts an innovative modular structure design to replace the traditional old-fashioned structure. The old-fashioned adhesive structure requires complex internal terminal wiring and cannot be powered off during operation. The disassembly and assembly of sensors and discharge valves are very complicated. The modular structure of Smart Drain overcomes this series of disadvantages, making use and maintenance more convenient.

Dostar Smart Drain is designed with fast discharge speed, high action frequency and strong overload capacity.

Dostar Smart Drain optional direct-acting solenoid valve has a simple structure, stable performance and long service life.

Dostar Smart Drain has complete specifications, providing users with a wide range of choices in terms of drainage, working pressure, applicable voltage and product materials.

Fault alarm function: When the water level is too high due to a failure in the drain, the sensor senses it in real time, automatically enters the self-cleaning drainage mode, and can remotely output a fault signal.

Dostar Smart Drain has been finalized through six major assessments: pressure test, flow test, impurity test, electromagnetic interference test, water spray test and life test, ensuring long life and high reliability.

The Unique Advantages of Dostar Condensate Drainers:

1.Dostar smart-drain is a pneumatic zero-gas consumption drainer, which can effectively discharge the condensed water according to the actual production volume. It only drains water without exhausting, avoiding the loss of compressed air.

2. Dostar smart-drain uses a specially designed floating ball, which is pneumatically controlled according to changes in liquid level, and realizes automatic drainage through the pneumatic drainage main valve without the need for an external air source.

3. Dostar smart-drain drain valve has a large hole diameter (the hole diameter of unpowered drainers on the market is generally about 1-2mm, which is easy to clog), and the drainage is smooth, and there is no fear of clogging.

4. When used only for compressed air smart drainage, smart-drain pneumatic drainers can be used in flammable, explosive and other hazardous environments.

5. Dostar smart-drain can provide special products for ultra-large water discharge, providing users with a wide range of choices.

6. Dostar smart-drain series pneumatic drainers have been finalized through four major assessments: pressure test, flow test, impurity test and life test, ensuring long life and high reliability.