GS Oil Seperator

-

Condensate Separators GS130/ GS260 Oil Water Separator

GS Condensate / oil Separator assists customers in protecting the environment, ensuring produce compliance with environmental regulations, and reducing the cost of hazardous waste disposal. The oil content in wastewater that can be directly discharged should be ≤20mg/L. By selecting and using the GS Condensate (Oil)Separator correctly, the oil content in the condensate can be controlled to ≤15mg/L (lowering the flow rate can achieve ≤10mg/L), purifying the wastewater to meet environmental discharge standards.”

Condensate Separators GS520/ GS1000/GS1580/GS2360 Oil Water Separator

Differing from typical single or double barrel oil-water separators, starting from GS520, Dostar pre-separation function, when handling larger processing capacities, will be more adaptable to harsh conditions, ensuring superior purification efficiency.

- Phone:+86-15371056062

- E-mail:sales@dostar-drainer.com

Detail

Product Details

The Importance of Condensate Separator

“When operating a compressed air system, a significant amount of condensate is generated, consisting primarily of water, lubricating oil, and other impurities. Typically, it is composed of about 99% water and 1% oil, where 1 liter of lubricating oil can contaminate 1000m³ of ground water. For a 15m³/min oil-injected rotary screw air compressor running for 8000 hours, the oil content in the condensate can reach 24 liters when calculated at 3ppm. Directly discharging condensate can lead to environmental pollution, and if treated as hazardous waste, the cost can be substantial.

GS Condensate / oil Separator assists customers in protecting the environment, ensuring produce compliance with environmental regulations, and reducing the cost of hazardous waste disposal. The oil content in wastewater that can be directly discharged should be ≤20mg/L. By selecting and using the GS Condensate (Oil)Separator correctly, the oil content in the condensate can be controlled to ≤15mg/L (lowering the flow rate can achieve ≤10mg/L), purifying the wastewater to meet environmental discharge standards.”

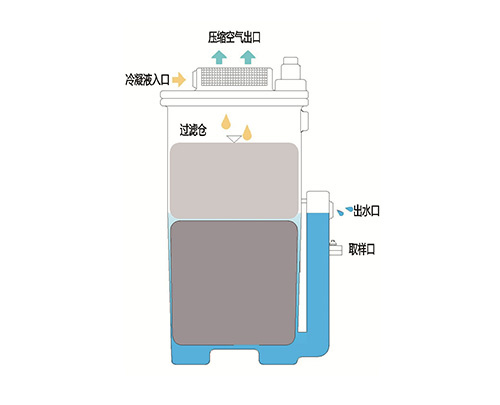

Working Principle

|

|

Performance Guarantee

|

1.The adsorption filter element is custom processed from polypropylene fiber material with excellent oil absorption performance, resulting in a strong adsorption capacity. 2. Special activated carbon material with high iodine value and high specific surface area ensures a superior water purification effect. |

|

|

Technical Parameters

|

Brand |

Dostar GS130 |

Dostar GS260 |

|

Compressor Machine Flow Rate |

4.2 |

8.3 |

|

Inlet size |

G1/2″ |

G1/2″ |

|

Outlet size |

G1/2″ |

G1/2″ |

|

Oil outlet size |

/ |

/ |

|

Maximum Operating Pressure |

16bar |

16bar |

|

Working temperature |

5-60 |

5-60 |

|

Material |

PE |

PE |

|

Size W×L×H(mm) |

455×390×780 |

455×390×780 |

|

Weight(kg) |

14 |

21 |

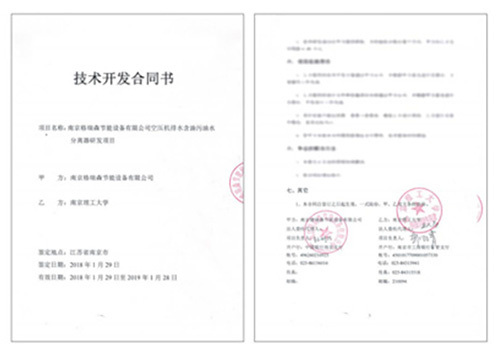

Technologically Advanced

|

The GS Condensate Separators, developed through collaboration between Dostar and Nanjing University of Science and Technology, relies on the technical support of the university. This ensures that the product’s structural design, data analysis, filter material selection, and scenario applications are all at the forefront of the market |

Test Reports and Certificates

Project Examples